Benefits of Tin Plating

Tin plating is a lower cost alternative than some

protective coatings. Tin also has a good level of conductivity enhancement

properties (as opposed to silver which has higher conductivity) which may be

of benefit to manufacturers seeking to enhance this property somewhat

without adding too much to the price.

Tin offers excellent solderability

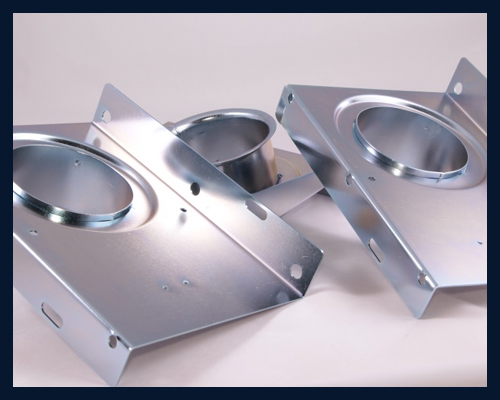

Tin can cover a wide range of shapes

and components

Tin provides corrosion resistance

Design Cautions

As this is

an electrolytic process it is necessary to use jigging, racking or wiring to

provide for electrical current conductivity. Some shapes lend themselves

more easily to this than others. In some cases the addition of a sprue or

hole is necessary. Please consult your plating adviser prior to finalising

design if you intend to use this finishing process.

Colour & Aesthetics

Tin

plating has a 'whitish grey' hue and is usuallyapplied without the layer of

bright nickel used in decorative coatings - as such tin has a dull, or matt

appearance.

Applications

Examples

include: electronic components such as electronic connectors or bus bars,

commercial cooking equipment and jewellery.

Substrates suited to this coating

Tin can be

plated over most metal substrates but commonly is used on lower value

substrates such as mild steel or copper alloys.